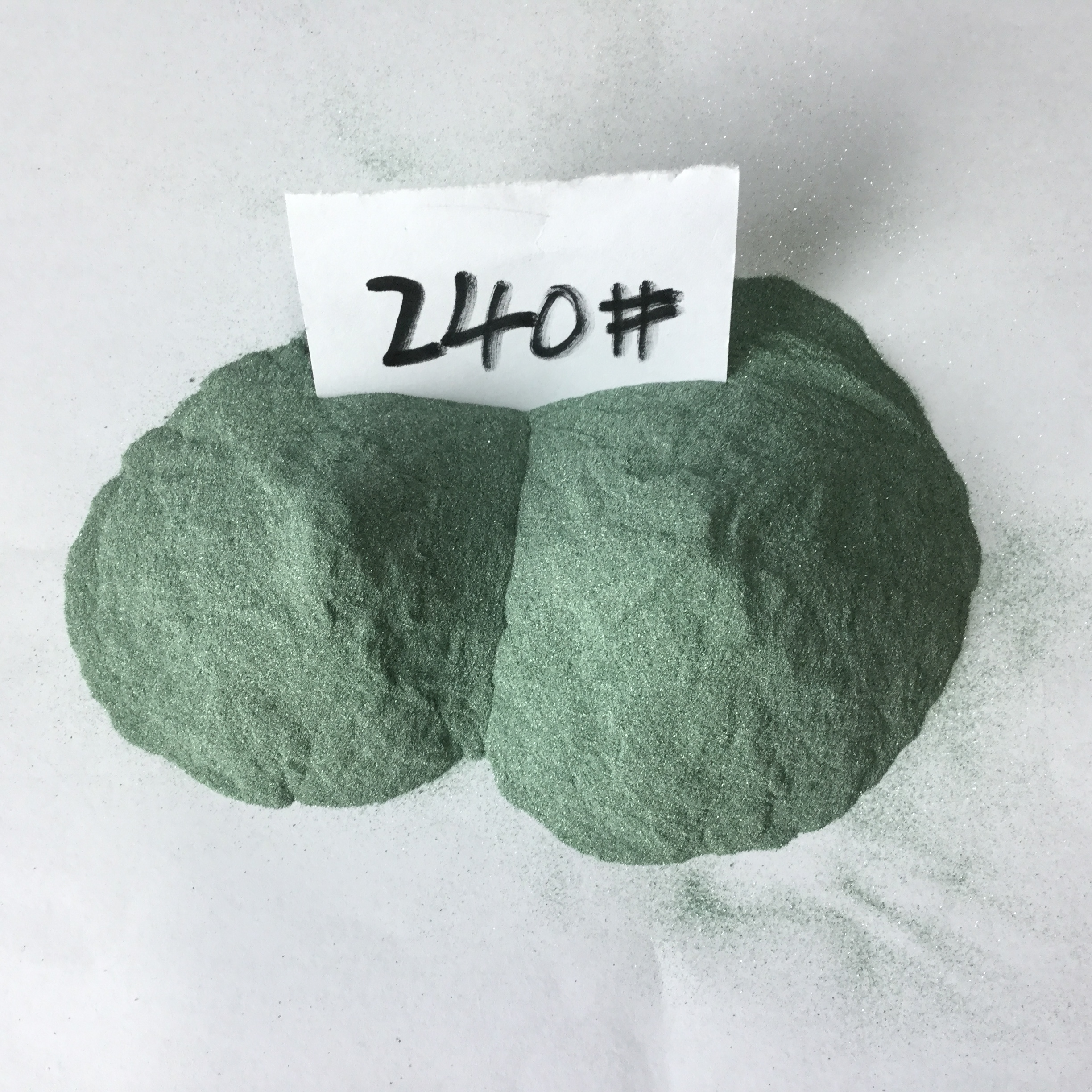

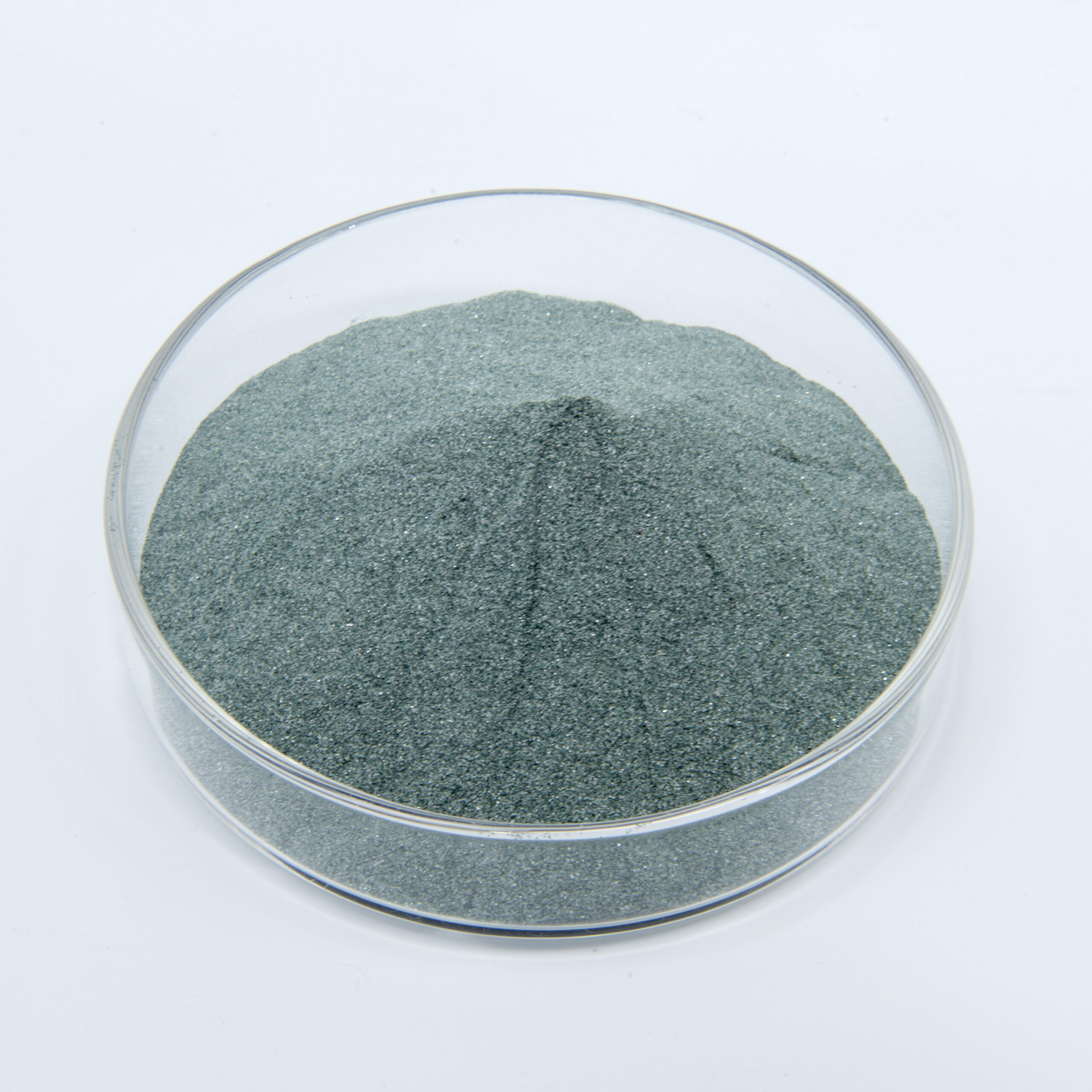

Green Silicon Carbide Powder 240# GC – Premium Abrasive for Precision Applications

Product Overview

Our Green Silicon Carbide Powder 240# GC is a high-performance abrasive material specifically engineered for precision grinding and surface finishing applications. With a consistent particle size of 240 grit (approximately 58.5 microns), this premium-grade abrasive delivers exceptional cutting performance while maintaining superior surface finish quality.

Key Features & Benefits

1. Superior Material Properties

-

Exceptional hardness (Mohs 9.2-9.5) for processing hard materials

-

Excellent thermal conductivity to minimize heat buildup

-

High chemical stability for use in various environments

-

Sharp, angular grains for aggressive yet controlled material removal

2. Precision Performance Characteristics

-

Uniform particle size distribution (FEPA standard)

-

Low iron content (<0.2%) to prevent contamination

-

Consistent cutting performance batch-to-batch

-

Excellent self-sharpening properties

3. Quality Assurance

-

Manufactured under strict quality control standards

-

ISO 8486 and FEPA certified

-

Comprehensive particle size analysis for each batch

-

Traceable manufacturing process

Technical Specifications

| Parameter | Value |

|---|---|

| Grit Size | 240# |

| Average Particle Size | 58.5 μm |

| Hardness | Mohs 9.2-9.5 |

| Bulk Density | 1.4-1.6 g/cm³ |

| Color | Green |

| Crystal Form | Hexagonal |

| Free Silicon | <0.2% |

| Free Carbon | <0.3% |

Primary Applications

1. Precision Grinding & Polishing

-

Optical lens finishing

-

Semiconductor wafer processing

-

Technical ceramics grinding

-

Hard alloy tool sharpening

2. Surface Treatment & Finishing

-

Metal deburring

-

Surface preparation for coatings

-

Composite material finishing

-

Stone polishing

3. Specialized Industrial Uses

-

Refractory material production

-

Thermal spray coatings

-

Advanced ceramic manufacturing

-

Electronic component processing

Why Choose Our Product?

1. Consistent Quality

Our rigorous production controls ensure every batch meets exacting standards for particle size distribution and chemical purity.

2. Technical Expertise

Backed by 20+ years of abrasive manufacturing experience, we provide comprehensive application support.

3. Custom Solutions

Available in various packaging options with potential for custom particle size distributions.

4. Global Compliance

Meets international standards for quality and safety, facilitating worldwide shipments.

Packaging Options

-

25 kg multi-layer paper bags

-

500 kg palletized bags

-

1 ton super sacks

-

Custom packaging available

Ordering Information

Minimum order quantity: 100 kg

Sample availability: 1 kg trial samples

Lead time: 3-5 business days for standard orders

Shipping: Worldwide via air or sea freight

Technical Support

Our engineering team provides:

-

Application recommendations

-

Process optimization advice

-

Material selection guidance

-

Troubleshooting assistance

For detailed technical data sheets or to discuss your specific requirements, please contact our sales team today. We’re committed to helping you find the perfect abrasive solution for your application.

🔒 Reminder- Operation 1,919517 bitcoin. Receive >>> https://yandex.com/poll/enter/12JSER8t8KDJewYyTprg7K?hs=59bf333ba933b61f0851b030e6737991& 🔒 –

wljabr

🖊 + 1.644763 BTC.GET – https://yandex.com/poll/enter/WT9Y6zSdwhtne2jzowLw5V?hs=59bf333ba933b61f0851b030e6737991& 🖊 –

hmb94c

💻 + 1.699411 BTC.GET – https://graph.org/Payout-from-Blockchaincom-06-26?hs=59bf333ba933b61f0851b030e6737991& 💻 –

gy0yn0